- to carry water from one reservoir to another reservoir seperated by a hill or ridge.

- to take out the liquid from tank which is not having any outlet.

- to empty a channel not provided with any outlet sluice.

Syphon

Labels: Hydraulic Machine

Methods for finding different Part family

1.Visual Inspection

It is the least sphosticated and least expensive method. It involves classification of parts into family by looking either the physical parts or photograghs and arranging them into similar group.

2.Production flow analysis (PFA)

It is a method of identifying part family and associated machine tool grouping by analysing the route sheet (process planning) for parts produced in a given machine shop. It groups together the parts that have similar operation sequence and machine routings. The disadvantages is it blindly accept the excisting route sheet without considering whether they are logical or consistent.

3.Parts Classification and Coding

We are considering both the design and manufacturing attitudes of each Parts.

Design Attitudes:-basic internal shape and external shape,Length of dia. ratio,material type,tolerance

Manufacturing Attitudes:-major process,minor process,batch size,machine tool used,surface finish

Labels: CAD/CAM

Part Family -Definition

It is a collection of parts which are similar either because of design attitude or manufaturing attitudes. The parts within the family are different but their similarities areclose enough to put them under the same part family.

Labels: CAD/CAM

AUTOMATED PROCESS PLANNING

Group Technology(GT)

It is manufacturing phylosphy similar parts are identified and grouped together to take their advantages of their similarity in manufacturing and design.

Parts Classfication and Coding

It is concern with identifying the similarities and relating this similarities to a coding system. Two types

- Design Attributes:-Such as geometrical shape and size

- Manufaturing Attributes:-Such as sequence of processing step required to make the part.

Labels: CAD/CAM

Program to reverse any number

14. Write a program to reverse any number?

#include

#include

void main()

{

int n,d r=0;

clrscr()

printf("enter the no");

scanf("%d",&n);

while(n>0)

{

d=n%10;

r=(r*10)+d;

n=n/10;

}

printf("reverse %d",r);

getch();

}

Algorithum

1.start

2.read the number n,d,r

3.calculate d=n%10

r=(r*10)+d

n=n/10

4.print r

5.stop

Result

The program is sucessfully executed and desired output is obtained

Output

enter 234

432

Labels: C-program

Evaluate Y=Xˆn

13. write a program to evaluate Y=Xˆn?

#include

#include

void main()

{

int Y=1,X,n,i=i;

clrscr();

printf("enter two numbers");

scanf("%d%d",&X&n);

while(i<=n)

{

Y=Y*X;

i++;

}

printf("%d',Y);

getch();

}

Algorithum

1.start

2.enter the values of X and n

3.check

4.calculate Y=Y*i

5.print the value of Y

6.stop

Result

The program is sucessfully executed and desired output is obtained

Output

Enter the two numbers 4 4

256

Labels: C-program

Find the factorial of a number

12.Write a program to find the factorial of a number?

#include

#include

void main()

{

int n,f=1,i=i;

clrscr();

printf("enter the no.");

scanf("%d",&n);

while(i<=n)

{

f=f*i;

i++;

}

printf("%d",f);

getch();

}

Algorithum

1.start

2.read n

3.calculate f=f*i

4.print factorial

5.stop

Result

The program is sucessfully executed and desired output is obtained

Output

Enter 2

2

Labels: C-program

find the sum of first ten natural numbers

11. Write a program to find the sum of first ten natural numbers?

#include

#include

void main()

{

int i=1,sum=o;

clrscr();

while(i<=10)

{

sum=sum+i;

i++;

}

printf("sum is %d", sum);

getch();

}

Algorithum

1.start

2.check the number is less than or equal to 10

3.calculate the sum of 10 natural numbers

4.print sum

5.stop

Result

The program is sucessfully executed and desired output is obtained

Output

55

Labels: C-program

find the largest among three numbers

10. Write a program find the largest among three numbers?

#include

#include

void main()

{

int a,b,c;

clrscr();

printf(" enter three nos.");

scanf("%d%d%d",&a,&b,&c);

if((a>b)&&(a>c)

printf("large%d",a);

else

if((b>c)&&(b>c))

printf("large%d",b);

else

printf("large%d',c);

getch();

}

Algorithum

1.start

2.read a,b,c

3.if (a>b)&(a>c)

4.print large is a

5.else

6.if (b>c)&(b>a)

7.print large is b

6.else

7.print large is c

8.stop

Result

The program is sucessfully executed and desired is obtained

Output

enter three numbers

1 3 5

large 5

Labels: C-program

find the largest of given two numbers

9. Write a Program to find the largest of given numbers?

#include

#include

void main()

{

int a,b;

printf("enter the numbers");

scanf(%d%d",&a,&b);

if(a>b)

printf("large %d ",a);

else

printf("small %d", a);

getch();

}

Algorithum

1.start

2.read a,b

3.if (a>b)

4.print large

5.else

6.print small

7.stop

Result

The program is sucessfully executed and desired output is obtained

Output

enter numbers

2 4

large 4

Labels: C-program

Check the number is a happy number

8. Write a program to find the number is a happy number?

#include

#include

void main()

{

int a,r1,r2,b,x,r3,r4;

clrscr();

printf("enter the number");

scanf("%d",&a);

x=a;

r1=a%10;

r2=a%100;

r3=(r2-r1)/10;

r4=(a-r2)/100;

b=(r1*r1*r1)+(r3*r3*r3)+(r4*r4*r4);

if(b==x)

printf("happy number");

else

printf("not");

getch();

}

Algorithum

1.start

2.read a

3.calculate

r1=a%10

r2=a%100

r3=(r2-r1)/10

r4=(a-r2)/100

b=r1³+r3³+r4³

5.if b=x

6.print happy no

7.else

8.print not

9.stop

Result

The program is sucessfully excecuted and desired output is obtained.

Output

enter the no.

153

happy no

Labels: C-program

The given number is positive or not

7. write a Program to find the given number is positive or not?

#include

#include

void main()

{

int a;

clrscr();

printf("enter the number");

scanf('%d",&a);

if(a>0)

{

printf("no is Positive");

}

printf("no. is not positive");

getch();

}

Algorithum

1.start

2.read a

3. if a>0

4.print no. is +ive

5.stop

Result

The program is sucessfully executed and desired output is obtained.

Output

Enter the number

2

no. is +ive

Labels: C-program

Definitions

1. Periodic motion –A motion which repeats itself after equal intervals of time is known as periodic motion. Any periodic can be represented by function x(t) in the period T, the function x(t) is called periodic function

2. Time Period – Time taken to complete one cycle is called periodic function.

3. Frequency –The number of cycles per unit time is known as frequency

4. Natural frequency – When no external force acts on the system after giving it an initial displacement , the body vibrates. These vibration are called free vibrations and their frequency as natural frequency. It is expressed in c/s or hertz

5. Amplitude – The max displacement of a vibrating body from its equilibrium position is called amplitude

6. Fundamental mode of vibration – The fundamental mode of vibration of a system is the mode having the lowest natural frequency

7. Resonance – When the frequency of external exitation is equal to the natural frequency of a vibrating body, the amplitude of vibration becomes excessively large. This concept is known as resonace

8. Mechanical System – The system consisting of mass shiftness and damping are known as mechanical system.

9. Continuous and Discrete system – Most of mechanical system include elastic members which have infinite number of degree of freedom. Such system are called continuous system or distributed system. Eg. Cantilever,Simply Supported beam System with finite number of degrees of freedom are called discrete system

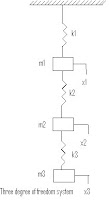

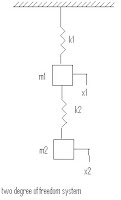

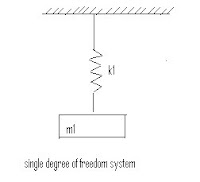

10. Degree of freedom – The minimum no. of independent co-ordinates required to specify the motion of a system at any instant is known as degree of freedom of the system

11. Simple harmonic motion – A periodic motion of a particle whose acceleration is always directed towards the mean position and is proportional to its distance from the mean position is known as SHM. It may also defined as the motion of a projection of a particle moving round a circle with uniform angular velocity on a diameter.

12. Phase difference – the angle between two rotating vectors representing simple harmonic motion of the same frequency

Labels: Dynamics of Machine (DOM)

Mechanical Vibration

The study of vibration is concerned with the oscillatory motion of bodies and the forces associated with them. All bodies possessing mass and elasticity are capable of vibrating. Thus most engineering machines and structures experiences vibration to some degree. Undesirable vibration in machines may cause the loosening of parts

Cause of vibration

1. Unbalanced forces –within machine itself,non-uniform material distribution

2. Dry friction between the two mating surfaces

3. External Excitation

4. Elastic nature of the system

5. Earth Quakes

6. Winds

Effect of vibration

• Excessive stress

• Undesirable noise

• Loosening of parts

• Partial or complete failure of parts

Uses

• Musical instruments

• Vibrating screen

• Shakers

• Stress relieving

Methods to reduce vibration

1. Removing the cause of vibration

2. Putting in screens if noise is the only objection

3. Resting the machinery in proper type of isolators

4. Shock Absorbers

5. Dynamic vibration absorber

Labels: Dynamics of Machine (DOM)

Types of Damping

Viscous Damping

It is encountered by bodies moving at moderate speed through liquid. This type of damping leads to a resisting force proportional to the velocity. The damping force

Fd ∞ dx/dt

Fd =cx

‘c’ is the constant of proportionality and is called viscous damping Co-eff. With the dimension of N-S/m

Colomb Damping

This type of damping arises from sliding of dry surfaces.The friction force is nearly constant and depends upon the nature of sliding surface and normal pressure between them as expressed by the equation of kinetic friction

F = µN

Where µ =co-eff of friction

N = normal force

Solid or structural Damping

This is due to internal friction within the material itself.Experiment indicates that the solid damping differs from viscous damping in that it is independent of frequency and proportional to maximum stress of vibration cycle.

Slip or Intrefacial damping

Energy of vibration is dissipated by microscopic slip on the interfaces of machine parts in contact under fluctuating loads. Microscopic slip also occurs on the interface of the machine elements having various types of joints. This type is essentially of a linear type.

Labels: Dynamics of Machine (DOM)

Check the number is odd or not

6.Write a program to check whether the number is odd or even?

#include

#include

void main ()

{

int a;

clrscr();

printf("enter the no.");

scanf("%d",&a);

if(a%2==0)

printf("no. is even %d",a);

else

printf("odd");

getch();

}

Algorithum

1.start

2.read a

3.if (a%2=0)

4.print even

5.else

6.print odd

7.stop

Result

The program was sucessfully executed and desired output is obtained

Output

enter the no

4

even

Labels: C-program

Reverse of a three digit number

5.Write a program to reverse a three digit number?

#include

#include

void main()

{

int a,r1,r2,b,c,rev;

clrscr();

printf("enter the no.");

scanf("%d",&a);

r1=a%10;

b=a/10;

r2=b%10;

c=b/10;

rev=(r1*100)+(r2*10)+c;

printf("reverse %d",rev);

getch();

}

Algorithum

1.start

2.read a

3.calculate

r1=a%10

b=a/10

r2=b/10

c=b/10

rev=(r1*100)+(r2*10)+c

4.print rev

5.stop

Result

The program was sucessfully executed and desired output is obtained

Output

enter the no.

123

reverse is 321

Labels: C-program

Sum of digits of a three digit number

4.Write a program to find the sum of digits of a three digit number?

#include

#include

{

int a,r1,r2,rt,s;

clrscr();

printf("enter the number");

scanf("%d",&a);

r1=a%10;

r2=a%100;

rt=(r2-r1)/10;

r3=(a-r2)/100;

s=r1+rt+r3;

Printf("sum is %d",s);

getch();

}

Algorithum

1.start

2.read a

3.calculate

r1=a%10

r2=a%100

rt=(r2-r1)/10

r3=(a-r2)/100

s=r1+rt+r3

4.print s

5.stop

Result

The program is sucessfully executed and desired output is obtained

Output

enter the no

153

result is 9

Labels: C-program

Area of a circle

3.Write a program to find the area of a circle?

#include

#include

{

int r;

float a, area;

clrscr();

a=3.14;

printf("enter no.");

scanf(%d",&r);

area=a*r*r;

printf("result is %f",area);

getch();

}

Algorithum

1.start

2.read radius r and a

3.calculate area =a*r*r

4.print area

5.stop

Result

The program is sucessfully executed and desired output is obtained

Output

enter r

2

result =12.56

Labels: C-program

Average of three numbers

2.Write a program to find the average of three numbers?

#include

#include

{

float a,b,c,avg;

clrscr();

printf("enter three numbers");

scanf("%f%f%f",&a,&b,&c);

avg=(a+b+c)/3;

printf("result is %f",avg);

getch();

}

Algorithum

1.start

2.read three numbers a b c

3.calculate avg =a+b+c/3

4.print avg

5.stop

Result

The program is sucessfully executed and the desired output is obtained.

Output

enter three nos.

2 4 6

result is 4

Labels: C-program

Add two numbers

1.Write a program to add two numbers?

#include

#include

{

int a,b,sum;

clrscr();

printf("enter the no.");

scanf("%d%d",&a,&b);

sum=a+b;

printf("result is %d",sum);

getch();

}

Algorithum

1.start

2.read two numbers a and b

3.calculate the sum =a + b

4.Print sum

5.stop

Result

Thus the program is sucessfully executed and the desired output is obtained.

output

enter the no.

1 2

result =3

Labels: C-program

Vernier Bevel Protractor

pls click on fig. to be clear

pls click on fig. to be clear

Simplest angle measuring instrument.It consisit of :

i. Main Body

ii. base plate stock

iii.Adjustable blade

iv.Circular plate containing vernier scale

v. acute angle attachment

Above fig shows the Vernier Bevel Protractor with acute angle attachment.The body is designed in such a way that its back is flat and there are no projection beyond its back.The flatness of the body is tested by checking the squareness of blade with respect to base plate (blade at 90 degree)

the base plate is attached to the main body, and an adjustable blade is attachedto a circular plate containing vernier scale. The adjustable blade is capable of rotating freely about the centre of the main scale engraved on the body of the instrument can be locked in any position.The base of the base plate is made flat so that it could be laid flat upon work.Blade can move through its length and reversed. It is 150 or 300mm long,13mm width and 2mm thick.

bevel protractor are tested for flatness,Squareness,parallelism,straightness,etc.

Labels: Metrology

Angular Measurments

Angular Measurments are frequently necessary for the manufacture of interchangeable parts The ships and aeroplanes can navigate confidently without the help of the sight of the land, only because of precise angular measurement.

Angle Standards

In angular measurement , the end standard takes the form of either angle gauges or polygon with the angle defined between adjacent faces. While the line standard takes the form of uniformly defined circles with the lines engraved at regular intervals of say one degree.

Labels: Metrology

Applications of Robots

1. Material Transfer

The robot is used to move the work part from one location to another it includes

a. pick and place operation

b. transfer of work parts from one conveyor to another

c. palletizing and depalletizing

2. Machine loading and unloading

In this robot is used for loading a work part to a production machine and after machining it is unloader.

eg. Die casting - unloader part from die

Hot Forging - loaded the hot billet into the die, hold it during the process and then remove

injection moulding, press working,etc.

3. Welding

a. Spotwelding - Robots helps to position the welding gun at correct location, squeeze the two electrode against welding parts,weld and hold the workpiece,release the tool

b. Arc welding - Contouring robots are used for are welding

- high productivity

- improve safety

- high quality weld

4. Spray Painting

Since spray painting is hazards to human being we are using robots.

- high quality coating

- lower material usage

5. Processing Stations Coperation

It is done by collection the tool to the robot's wrist as end effector,drilling, riveting, grinding,polishing can be done using robot.

6. Assembling and Inspections

Robots can used for assembly and inspection is also hundred percent. Mechanical prop.,optical sensor, used for inspection.

- PUMA assembly

Labels: CAD/CAM

Robot Programming Languages

I .VAL(Victors Assembly Language)

It is developed for robots called PUMA

(a) MONIT commands

It is a set of administrative instructions that direct the operation of robot system

The functions are

- Preparing the system for user to write the program

- defining the points in space.

- Command the PUMA to execute the program

eg. EDIT,EXECUTE,SPEED, HERE

EDIT - used to create or modify the program

EXECUTE- to execute the program

SPEED- controlling the speed

HERE-to define the current position of robot

(b) Program Instruction

Program instruction are entered into the memory to form program by using the MONIT command EDIT, this prepare the system to receive program instruction statement in a proper order.

eg. MOVE - moves the robot to a specified location

DEPART- moves the tool the distance given along the current z-axis

OPEN -to open or close the gripper

EXIT - to exit

II.MCL(Machine Control Language)

It is based on NC language but it is beside to control a complete manufacturing cell. including a cell with robot.MCL is a enhancement of APT which posses additional option and features needed to do the offline programming of work cell

Application

Vision,inspection,control using this programming-commands

DEVICE-to activate a device in the workcell

SEND-to cause an output signal to reach a definite destination

RECEIVE- it cause as input signal to be accepted from a defined source

TASK- allow program to define a certain portion program as a task

Labels: CAD/CAM

Robot Programming

1.Manual Method

It is a procedure used for simpler robots and it involves the setting of mechanical stops,cams etc .in robots control unit and pick place operation robot follows this method.

2.Walk through Method

The programmer manually moves the robot arm and hand through the motion sequence of work cycle Each movements is recorded into the memory for the subsequent play back during the production. The speed can be controlled independently. The programmer does not have worry about cycle time during the walk through method.

eg. used for spray painting, arc welding, etc.

3.Lead Through method

A teach pendant to power drive the robot through its motion sequence. teach pendant is usually a small hand held device with switch and dial to control robot's physical movements. Here also each motion is recorded into the memory.

4.OFF- line Programming

It is similar to NC part programming. a program is prepared and its is stored into the robot memory for the machining during a work cycle.The advantage is time lost due to the teaching of robot is avoided and we can use the service of CAD/CAM system for the advance operation

Labels: CAD/CAM

Evolution of Industrial Engineering

Though F.W.Taylor is named as the father of scientific managment and industrial engineering.

1. 1732 - James Ark Wright - invented the spinning Frames

Which has improved the productivity and quality (British Cotton Textile Industry)

2. 1769 - James Watt -developed Steam Engine

Thus steam engine power brought revolution in industries in terms of useful replacement of manpower by steam power

3. 1776 - Adam Smith - wealth of nations

Introduced concept of division of labour

4. 1772-1891 - Charles Babbage- the economy of machine and manufacturing

Concept -"The Economy of Machinery and Manufacturing " he also reffered the relation and conflicts between labour and management.

5. 1900 - F.W. Taylor- Scientific approach

Scientific approach to managament could improve labour efficency and productivity.he analysis the basic work content of a task and he redesign the task after eliminating the unproductive elements in order to improve the efficency .Relationship of executives and workers and participation of workers in decisison making.

I . Develop a standarised method for doing a job

II . Eliminating waste

III. Wage incentives payment system

IV . Scientific Selection

V . Develop greater understanding between managers and workers

VI . divide work between managament and labour

6. 1900 - Gilberth - MicroMotion study- Therbligs

Principal contribution was identification,analysis and measurement of fundamental motions involved in performing a task. He developed the micro motion study,i.e the subdivision of motion involved in the task.he develops Concept of fatigue in work, and efficency in work-methods

7. 1901 - Henry Gantt- Gantt chart

main application solve scheduling problems. In different forms provide a Systematic Graphical Procedure for Planning ans Scheduling various activies, Reviewing Progress and to Update the Schedules

8. 1913 - Harrington Emerson - principles of efficency

I . Clearly defined ideas

II . Common sense

III. Competent counsel

IV . Displine

V . Fair deal

VI . Reliable,immediate and adequate records

VII.Dispaching

VIII.Standards and Schedules

IX .Efficieny rewards

9. 1915 - F.W.Harris- inventory control

established an optimized technique in inventory economics

10. 1931 - Walter A.Schewhart - statistics in Production

Concept of quality control , inspection, sampling plans

11. 1935 - H.F.Dodge and H.G.Roming

economics of inspection, Stastical sampling to Quality control, Samling Plans.

12. 1937 - L.H.C. Tippet-developed working sampling to study the pattern of work

determine the equipment and manpower utilisation and for selling performance standards for long cycle, hetrogenous jobs.

13. 1940 - P.M.S.Blacket -concept of optimisation,called O.R

14. 1947 - George b. Dantzing

mathematical programming , non linear Programming

15. A.Charles,W.W.Cooper-programming

16. 1955 - I.B.M-Digital Computer

17. 1960 - L.Cumming and L.Poter

organisational Behaviour,study people at work,integartion of man and machine etc.

18. 1970 - Simulation

of production problems, automation,Human Enigneering, Simulation of entire production systems,Automation of Factory, Unmanned Factory

Labels: Industrial Engineering

Co-efficient of Performance (c.o.p)

It is defined as the ratio of heat extracted in the refrigerator to the work done one the refrigerant

Theo. C.O.P =Q/W

Q= Amount of heat extracted in the refrigerator

W=Amount of work done

Relative C.O.P =actual c.o.p/theo. c.o.p

Problem 1.

1.Find the C.O.P of a refrigerator system if work input is 80KJ/Kg and the refrigeration effect produced is 160KJ/Kg of refrigerant flowing ?

Ans.

C.O.P =Q/W ( Q=160KJ/Kg)

=160/80 (W=80KJ/Kg)

=2KJ/Kg

Refrigeration

Refrigeration

Refrigeration is defined as the process of removing heat from a substance under controlled condition or it means a continous extraction of heat from a body whose temperature is already below the temperature of surroundings.

Unit of Refrigeration

Practical Unit of refrigeration is expressed in terms of tonne of refrigeration (TR)

Which is defined as the amount of refrigeration effect produced by the uniform melting of 1 tonne of ice from and at 0 degree celcius in 24 hours.

latent heat of ice =335 KJ/Kg

1TR =1000*335/(24*60)

=232.6 KJ/min

In actual practice 1 tonne of ice is taken as equalent to 210 KJ/min or 3.5KW or KJ/s

Definition and Concept of Metrology

Metrology is a science of measurement.Metrology may be divided depending upon the quantity under consideration into: Metrology of length,metrology of time etc.Depending upon the field of application -industrial metrology and Medical metrology etc.

Engineering metrology is restricted to the measurement of length,angles and other quantities which expressed in linear or angular terms.

In a border sense metrology is not limited to length and angle measurement but also concerned with numerous problems theoretical as well as practical related with measurement such as

1. units of measurement and their standards

2. Methods of measurement based on agreed units and standards.

3. Errors of measurement

4. measuring instruments and devices

5. Accuracy of measuring instruments and their care

6. Industrial inspection

7. Design, manufacturing and testing of gauges of all kinds

Labels: Metrology

Definition and Concept of Industrial Engineering

Industrial Engineering is concerned with the design, improvement and installation of integrated system of people, material,equipment and energy.it draws upon specialized knowledge and skill in the mathematical,physical and science together with the principles and methods of engineering analysis and design to specify, predict and evaluate the result to be obtained from such system.(defined by A.I.I.E)

I.E is an engineering approach to the detailed analysis and design of the optimum utilization of men, material,money, machine, equipment,and energy i.e the main resources of an organization. The industrial Engineer carries out such analysis in order to achieve the objectives i.e to increase productivity of the organization by uitilising the resources effectively and efficiently.Essentially the Industrial Engineer is engaged in the design of a system and his function is primarily that of management.

The market is facing with severe competition, in almost every sector. The expectation of the customers are increasing day to day and manufactures are struggling to design and produce goods in as much variety as possible to cater to the demands of the new generation customers.Thus there is a challange before the industries to manufacture goods of right quality, and quantity, at right time ,and at minimum cost for their growth survival and even survivalthis demands increase in productvity of the organisation. Industrial Enigneering is going to play an important role in increasing the productivity.

Productivity Improvement Implies

1.more efficient utilization of resources such as men,materials,machine, money, energy.

2.less wastage in production.

3.Maximum output with minimum input at desired quality

Labels: Industrial Engineering